Epoxy.com Technical Data

Installation Instructions

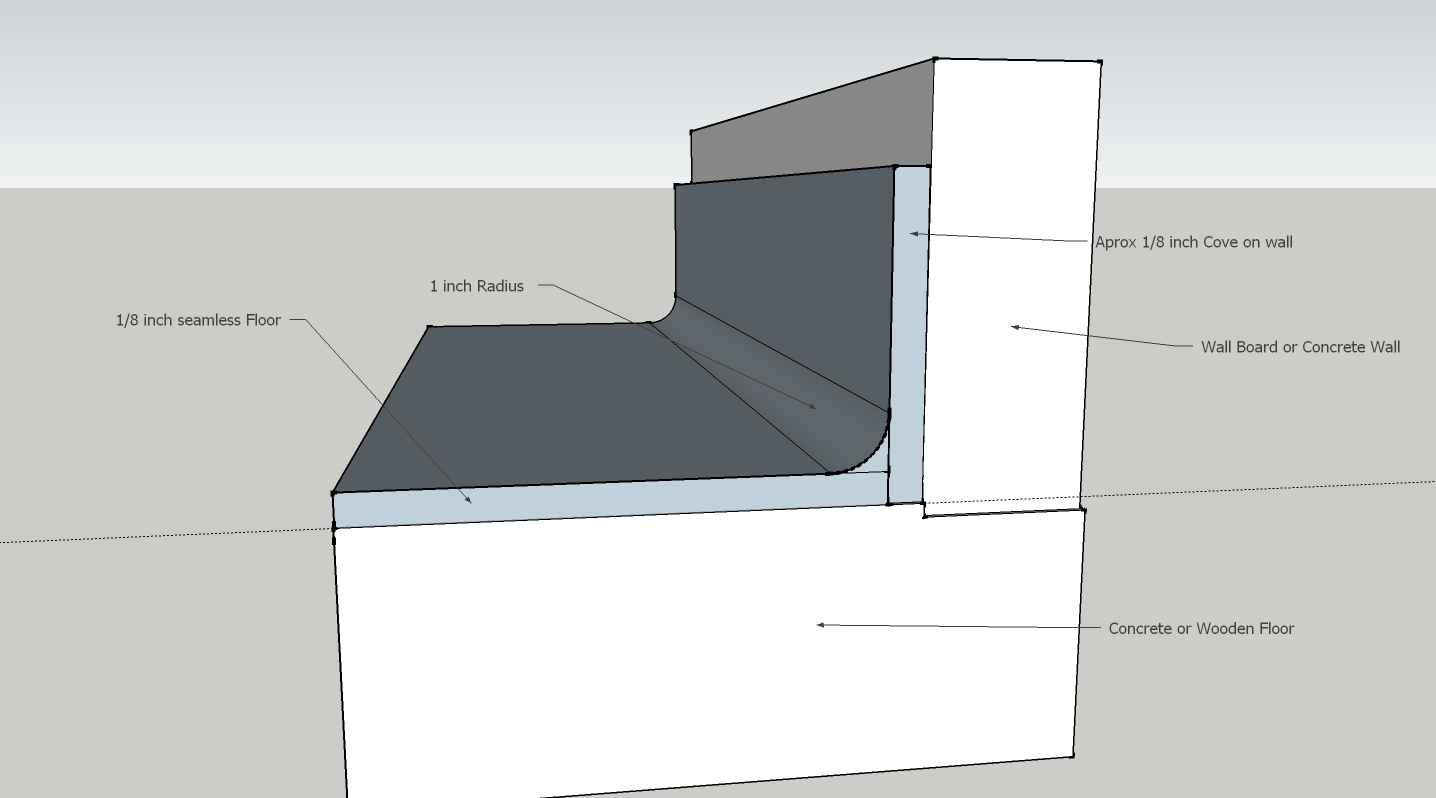

Epoxy Cove Base

Product #720 Cove Paste

Binder Method

I. GENERAL INFORMATION

Most Epoxy.com FLOORING SYSTEMS can be installed with an

integral cove base to provide seamless wall to floor protection. The

outline below explains mixing and installation procedures for each

type of system.

II. SURFACE PREPARATION

Surface Preparation is the most critical portion of any

successful resinous flooring system application. All substrates must

be properly prepared as outlined in Epoxy.com Surface Preparation

Guide. Specific attention should be paid to the following:

A. Concrete placement

B. Curing and finishing techniques of the concrete substrate

C. Age of concrete

D. Previous contamination of the substrate

E. Present condition of the substrate

Also, the temperature and humidity conditions of the area to receive

the flooring system should be checked. An optimum room temperature

of 75°F with a minimum slab temperature of 50°F is required for

proper cure of the resin flooring system.

III. COVE BASE FOR Epoxy.com Product #15 QUARTZ SYSTEMS

If you are installing Epoxy.com Chip Flooring or and other Epoxy.com

Flooring or Mortar System Except for Epoxy.com Product #15 Quartz

System skip ahead to Section IV.

Installations of an integral cove base with Epoxy.com Flooring

is normally terminated at the floor line by cutting a straight line

at the bottom of the cove and installing the system up to that

point. The top of the cove can terminated with a divider strip.

Alternate method involves masking a line with Duct Tape at the top

of the cove. If using the duct tape method, be sure to remove the

duct tape before the cove sets up too much to remove the duct tape

properly.

A. Material Quantities

1.

Epoxy.com #899 Primer/ Low Modulus Binder 1

gallon

2. Epoxy.com #720 Cove Paste Binder 1.25

gallons

3.

Epoxy.com Quartz Granules 100

pounds

4. Epoxy.com #60 Cove Powder 1 quart

Recommended batch quantities

1 Quart Epoxy.com #720 part A & 1 cup

Epoxy.com #720 part B

2. 24 pounds Epoxy.com Colored Quartz Granules

3. 1 Cup Epoxy.com # 60 Cove Powder

Estimated Batch Coverage: 22-25 lineal feet

at 1/8"

B. Installation--Priming

It is very important to prime the wall surface prior to

installing cove base. Priming insures maximum adhesion to

the prepared substrate and helps mixed cove material to

"hang" on the wall.

1. Mixing

Epoxy.com #899 Low Modulus Epoxy

Primer

a. Stir each component prior to

mixing.

b. Mix two (2) parts by volume of

Part A (Base) with one (1) part by

volume of Part B (Hardener) for

three minutes with a low speed

electric drill mixing paddle.

c. If thinning is desired, add no

more than one pint of xylene per

gallon of epoxy at time of mixing.

d. Mix only that amount of

material that can be used in 40

minutes.

e. Apply only as much primer

as you can apply the Product #720

Cove mix to before the 899 Primer

hardens and is no longer tacky.

2. Application--Brush primer onto the

wall surface.

3. Allow Primer to tack-up.

C. Installation--Cove Base

Note: Cove Base should be applied into the 899

Primer, while the 899 Primer is still tacky. If the

899 Primer is no longer tacky, reapply the 899

Primer.

1. Mixing Epoxy.com #720 Cove

Paste Binder, Quartz Granules, & Cove

Powder

a. Stir each component prior to

mixing.

b. Mix four (4) parts by volume of

Part A (Base) with one (1) part by

volume of Part B (Hardener) for

three minutes with a low speed

electric drill mixing paddle.

c. Transfer to KOL mixer and add

Epoxy.com Cove Powder to the

premixed Epoxy.com #720.

Note: Epoxy.com recommends the use of a KOL

Mixer when preparing cove base material.

Insufficient mixing of cove base material will

result in a stiff, dry, and hard to trowel blend

that does not have sufficient wetting of aggregate

to insure proper bonding to the substrate.

d. Continue mixing while adding Epoxy.com

Colored Quartz Granules.

e. Mix resin/aggregate mortar for 3 to 4

minutes or until aggregate uniformly is wet.

2. Application

a. Trowel cove base mixture vertically onto primed

wall surface at 1/8" thickness.

b. Place material at the cove and form cove radius

using and appropriate cove trowel.

c. Terminate bottom of cove base and install quartz

flooring up to base.

IV. COVE BASE FOR Epoxy.com MORTAR, and Epoxy.com

Chip Flooring Systems

Installations of an integral cove base with Epoxy.com

Solid Colored Floor Systems

are normally terminated at the floor line by cutting a

straight line at the bottom of the cove and installing the

system up to that point. The top of the cove is preferably

terminated with a divider strip as pictured in the following

pages.

A. Material Quantities

1.

Epoxy.com #899 Primer/Low

Modulus Binder 1 gallon

2. Epoxy.com #720 Cove Paste

Binder 1.25 gallons

3. Epoxy.com Blended Mortar Aggregate

100 pounds

4. Epoxy.com #60 Cove Powder 1

quart

Recommended batch quantities

1. 1 QT Epoxy.com #720 part A & 1

cup Epoxy.com #720 part B

2. 21 pounds Epoxy.com Blended Mortar

Aggregate

3. 1 pint Epoxy.com Cove Powder

Estimated Batch Coverage: 22-25

lineal feet at 1/8 inch thick.

B. Installation--Priming

It is very important to prime the wall surface prior to

installing cove base. Priming insures maximum adhesion to

the prepared substrate and helps mixed cove material to

"hang" on the wall.

1. Mixing Epoxy.com #899 Low

Modulus Epoxy Primer

a. Stir each component prior to

mixing.

b. Mix two (2) parts by volume of

Part A (Base) with one (1) part by

volume of Part B (Hardener) for

three minutes with a low speed

electric drill mixing paddle.

c. If thinning is desired, add no

more than one quart of xylene per

gallon of epoxy at time of mixing.

d. Mix only that amount of

material that can be used in 40

minutes.

e. Apply only as much primer

as you can apply the Product #720

Cove mix to before the 899 Primer

hardens and is no longer tacky.

2. Application--Brush primer onto the

wall surface.

3. Allow Primer to tack-up.

C. Installation--Cove Base

Note: Cove Base should be applied into the 899

Primer, while the 899 Primer is still tacky. If the

899 Primer is no longer tacky, reapply the 899

Primer.

1. Mixing Epoxy.com #720 Cove

Paste Binder, Mortar Aggregate, & Cove

Powder.

a. Stir each component prior to

mixing.

b. Mix four (4) parts by volume of

Part A (Base) with one (1) part by

volume of Part B (Hardener) for

three minutes with a low speed

electric drill mixing paddle.

c. Transfer to KOL mixer and add

Epoxy.com Cove Powder to the

premixed Epoxy.com #60.

Note: Epoxy.com recommends the

use of a KOL Mixer when preparing cove base

material. Insufficient mixing of cove base material

will result in a stiff, dry, and hard to trowel

blend that does not have sufficient wetting of

aggregate to insure proper bonding to the substrate.

d. Continue mixing while adding Epoxy.com

#77 Mortar Aggregate

e. Mix resin/aggregate mortar for 3 to 4

minutes or until aggregate uniformly is wet.

2. Application

a. Trowel cove base mixture vertically onto primed

wall surface at 1/4" thickness.

b. Place material at the cove and form cove radius

using and appropriate cove trowel.

c. Terminate bottom of cove base and install mortar

flooring up to base.

D. Installation--Grouting and Sealing

The grouting and sealing of the floor should be

performed over the entire area receiving the system.

The cove base should also receive the same grout and

seal coats as the finished floor in order to provide

proper performance and appearance. See installation

instructions for each system to be installed.

Here is additional information on the

installation of this cove.

Do you need to estimate the material required for your job? Use the

Epoxy.com Epoxy Coving Material Calculator.

Click the Picture Above for a Larger View